- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

English

English English

English| Availability: | |

|---|---|

| Quantity: | |

103

KSeng

KSeng-103

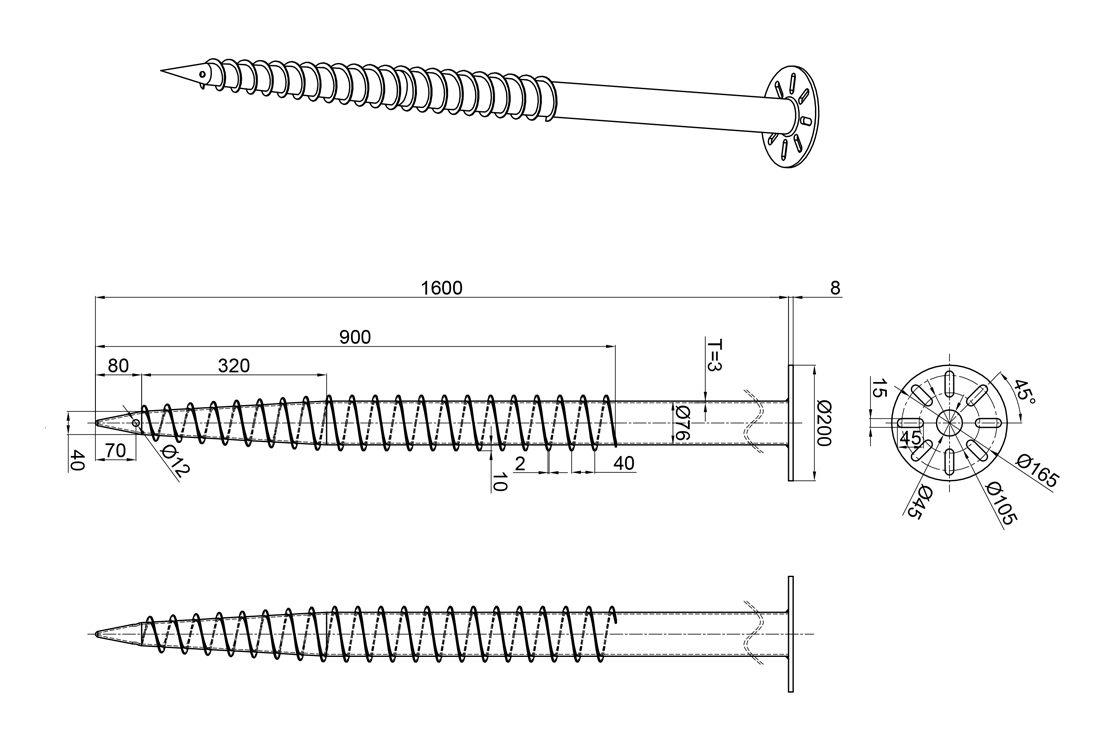

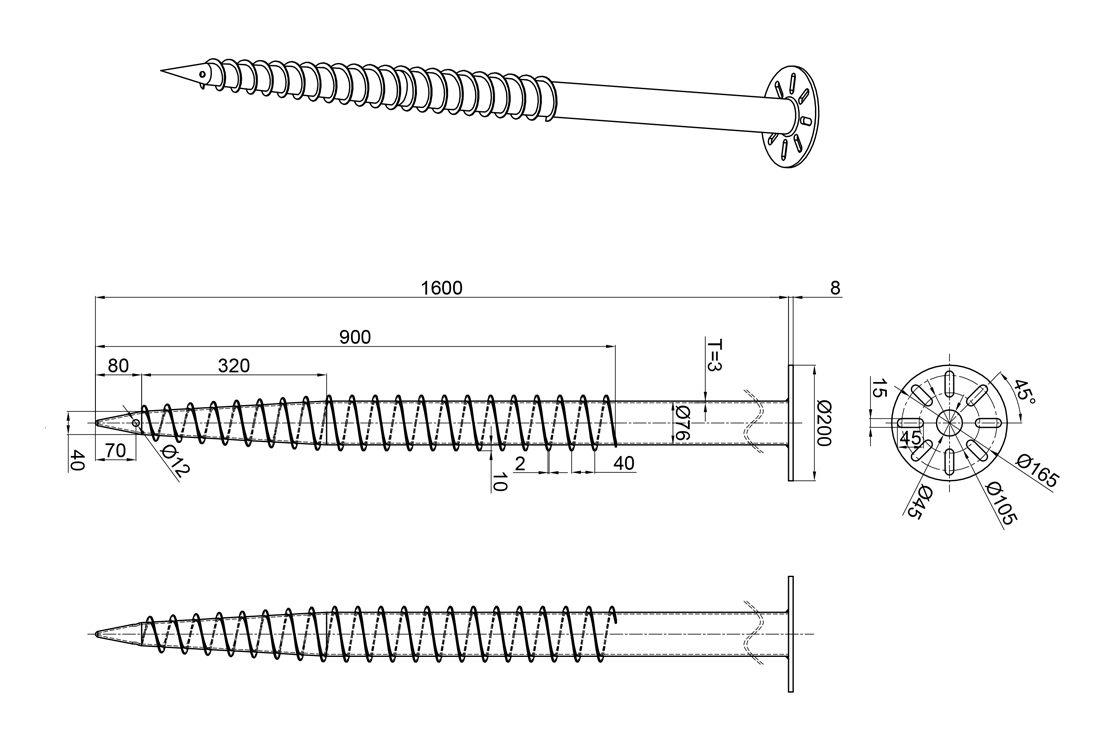

The Solar ground screw usually made of galvanized steel with a helical blade at the bottom. This design allows it to easily penetrate a variety of soil types, providing stability and reliable support.

To install, ground screws are screwed directly into the ground by means of a hydraulic actuator or hand-held tool. As the screws are inserted, the spiral blades expand, creating a firm grip in the soil. This installation eliminates the need for a traditional concrete foundation, resulting in significant time and cost savings.

| Product Name | Factory Direct Sale Solar Ground Screw Piles for Solar Mounting |

| Material | Hot Dip Galvanizing Q235B |

Outer Diameter | 76mm |

| Length | 1000-3000mm |

| Thickness | 3-3.5mm |

Flang Diameter | 200mm&220mm |

| Warranty | 10 Years Warranty, 20 Years Service Life |

| application | Solar Lighting |

| solar ground mount | |

Bollard Lighting | |

Awnings | |

| Others | support customized |

Advantages:

1. Time and Cost Savings: Solar ground screws significantly reduce the time and cost associated with traditional concrete foundations. They require less excavation, curing time, and heavy machinery, resulting in faster and more cost-effective installations.

2. Environmental Impact: Compared to concrete foundations, solar ground screw piles have a lower environmental impact as they require less concrete and produce less soil disturbance during installation.

3. Durability: Made from high-quality materials, solar pv module bracket ground screws offer excellent durability and resistance to corrosion, ensuring the long-term stability and performance of the solar energy system.

4. Flexibility: Solar ground screws can be easily relocated or adjusted if needed, providing flexibility in system design and future expansion.

5. Longevity: The ground anchor screw is made of durable materials, such as galvanized steel, ensuring long-term

performance and resistance to corrosion and degradation. They provide a reliable foundation for solar panel

arrays for many years.

The Solar ground screw usually made of galvanized steel with a helical blade at the bottom. This design allows it to easily penetrate a variety of soil types, providing stability and reliable support.

To install, ground screws are screwed directly into the ground by means of a hydraulic actuator or hand-held tool. As the screws are inserted, the spiral blades expand, creating a firm grip in the soil. This installation eliminates the need for a traditional concrete foundation, resulting in significant time and cost savings.

| Product Name | Factory Direct Sale Solar Ground Screw Piles for Solar Mounting |

| Material | Hot Dip Galvanizing Q235B |

Outer Diameter | 76mm |

| Length | 1000-3000mm |

| Thickness | 3-3.5mm |

Flang Diameter | 200mm&220mm |

| Warranty | 10 Years Warranty, 20 Years Service Life |

| application | Solar Lighting |

| solar ground mount | |

Bollard Lighting | |

Awnings | |

| Others | support customized |

Advantages:

1. Time and Cost Savings: Solar ground screws significantly reduce the time and cost associated with traditional concrete foundations. They require less excavation, curing time, and heavy machinery, resulting in faster and more cost-effective installations.

2. Environmental Impact: Compared to concrete foundations, solar ground screw piles have a lower environmental impact as they require less concrete and produce less soil disturbance during installation.

3. Durability: Made from high-quality materials, solar pv module bracket ground screws offer excellent durability and resistance to corrosion, ensuring the long-term stability and performance of the solar energy system.

4. Flexibility: Solar ground screws can be easily relocated or adjusted if needed, providing flexibility in system design and future expansion.

5. Longevity: The ground anchor screw is made of durable materials, such as galvanized steel, ensuring long-term

performance and resistance to corrosion and degradation. They provide a reliable foundation for solar panel

arrays for many years.